BOTHELL — Carbon-fiber composites, the materials used to build airplanes and wind turbines, are a lot like fresh fruits and veggies.

They’re perishable. They require refrigeration — and when they hit their expiration date, they’ve got to be tossed.

Some composites are recycled, but “most go straight to the landfill,” said Andy Buchan, an aerospace engineer by training.

ASX Composites, a Bothell startup, hopes to lower the manufacturing and storage costs tied to the production of composite materials, steps that could reduce the industry’s carbon footprint.

“We’re at the stage where we’re looking for partners to demonstrate our capability,” said Buchan, the company’s vice president of strategy and business development.

Some 30% to 40% of composite materials are scrapped due to their short shelf life, he said. That’s right up there with fruits and vegetables, which make up 39% of food waste in the U.S.

End users typically end up eating those costs, adding to the product’s expense, he said.

Because of the chemistry involved in making a carbon fiber composite, the material must be kept chilled.

Once you’ve cooked up a batch — and it’s usually manufactured in large quantities — “it decays rapidly,” Buchan said.

To keep it fresh, it goes into a special fridge, but it takes a boatload of electricity to store in a refrigerator the size of a small house.

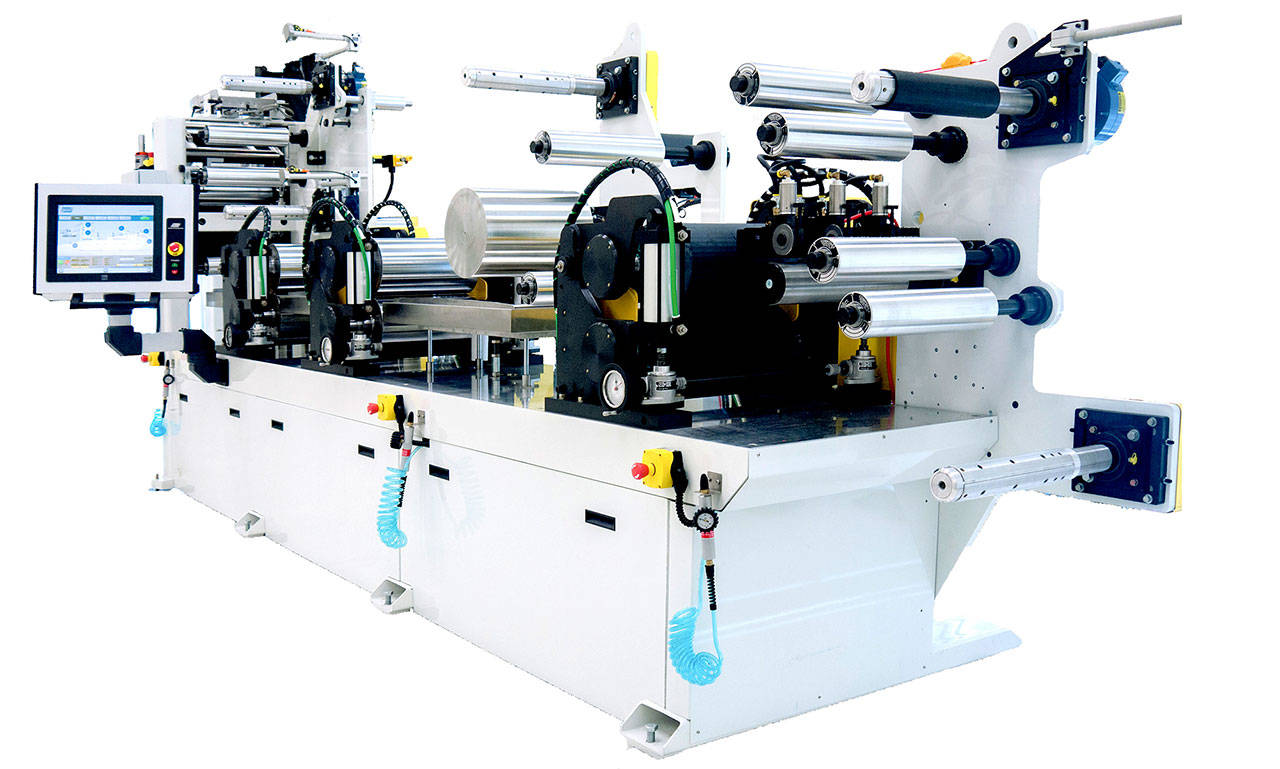

ASX has developed a line of patented machines that can manufacture composite materials on site, as needed, and in small batches.

The system could be a fit for companies in need of smaller quantities, such as a sports equipment manufacturer, Buchan said. “It’s that specialty need that we’re looking to service,” he said.

ASX machines are the size of an airport shuttle and can be deployed on a factory floor.

Because the equipment can produce composite material in small quantities, there’s room to tweak the recipe.

That could include altering the chemical composition of the resin that’s mixed with the carbon fibers, a feature that can “free up design choices,” Buchan said.

That’s a switch from the current process by which composites are produced in large batches and then transported on refrigerated trucks — another energy drain — to another factory to be cut into strips or sized for a specific manufacturing application, Buchan said.

ASX machines could wrap the process into a single operation and yield savings that lower storage and transportation costs and slash greenhouse gas emissions, Buchan said.

Composite materials have been on the scene since the 1960s, but their use has exploded in the past 20 years.

Formed from graphite, carbon fibers are mixed with resin to create a composite material that’s five times stronger than steel but lighter in weight.

Lighter and more durable than most metals, composites have become a staple in the aerospace and wind turbine industry and are making inroads among high-end automakers.

The entire 235-foot wing of Boeing’s new 777X is made of a carbon fiber composite and, according to Boeing, that makes it the largest piece of composite material in the world. Plus, nearly half of the Boeing 787 is comprised of carbon fiber reinforced plastic and other composites.

“It’s an expensive material,” said Buchan, and “you don’t want to be throwing it away.”

Janice Podsada; jpodsada@heraldnet.com; 425-339-3097; Twitter: JanicePods

Talk to us

> Give us your news tips.

> Send us a letter to the editor.

> More Herald contact information.