This is one of a series of Herald Business Journal stories about the people and companies behind locally made products.

SNOHOMISH —Three years ago, a sales rep walked into Valley Orthodontic Laboratory and handed the new owner, Jim Beierle, a plastic night guard.

“It was nothing special,” Beierle recalled.

Then the rep dropped a bomb: It had been made on a 3-D printer.

“It was everything my dad and I had ever talked about. It was the way of the future,” said Beierle, who bought the business from his father, Udo, in 2016.

“Until then, we’d been making mouth guards by hand,” Beierle said.

Three-D printing, more formally known as additive manufacturing, has been around for more than 100 years but only became commonplace in recent decades.

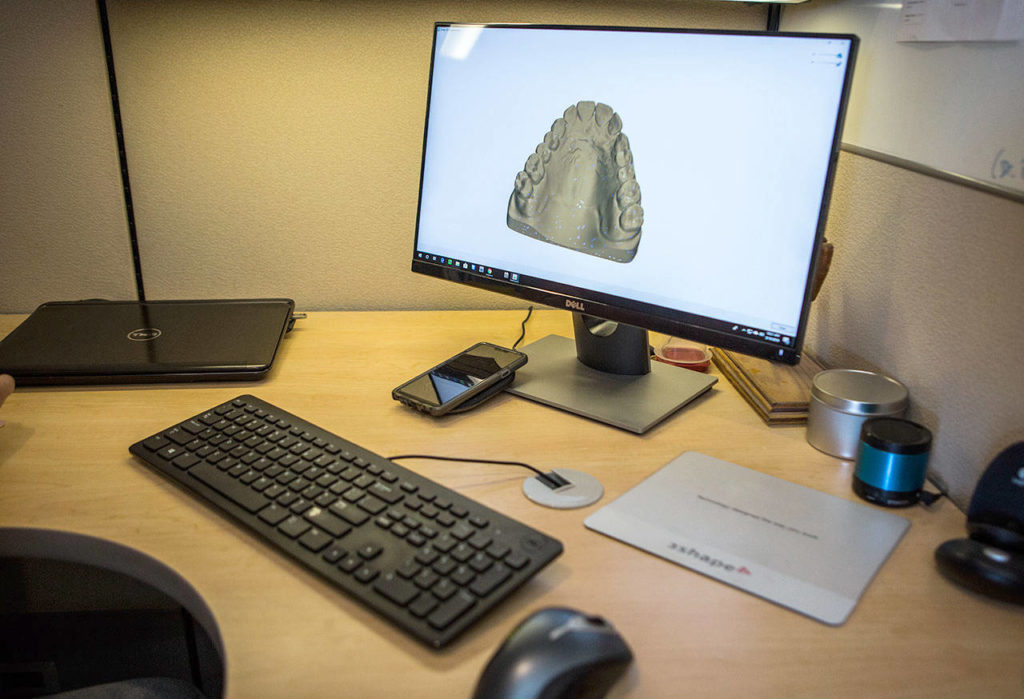

In the past three years, 3-D printers and scanners and the accompanying software have transformed dental devices and equipment, an $18 billion annual industry, according to IBISWorld, a New York consulting firm.

Soon after, Beierle invested $100,000 in 3-D printers and scanners for the lab.

The first month, he made only 14 dental devices with the new equipment — and tossed and turned at night.

“I was worried about whether it would pay for itself,” he said.

His timing, however, was right on. More dental professionals began abandoning mold technology and adding digital scanners to create virtual 3-D models of patients’ teeth and gums.

For decades, molds — a direct impression of a patient’s bite — was the standard for fashioning custom mouth guards, retainers and braces.

That’s changing. And here’s why it’s a big deal: If you’ve sat in a dentist’s chair and clamped down on a mouthful of dental putty for 20 minutes, you know how uncomfortable that can be.

You might even have tolerated the ordeal by telling yourself that your suffering guaranteed an accurate impression.

But you’d be wrong.

A strong gag reflex can create ripples and streaks in the resulting mold, Beierle explained.

“As a dentist, all you could say was ‘this is the best we could do because the kid was gagging the whole time,’” Beierle said.

Dr. Paul Kulits, who recently installed scanners at his orthodontic offices in Everett and Arlington, agrees. “Digital models are more accurate,” said Kulits, who’s been practicing for 26 years.

As an added bonus, Kulits’ storeroom is becoming a little less crowded. Dental professionals typically store their patients’ plaster molds longer than a tax return. Digital models, however, reside in the cloud, freeing up space.

Valley Orthodontic now prints 200 dental devices and night guards each month and has doubled its workforce. It’s client base has risen from 50 to 70.

“The equipment paid for itself in the first year,” Beierle said.

Now that dental offices can push a button and transmit digital files, it serves dentists across the U.S., including Alaska, California, Colorado, Georgia, New York and Virginia.

Three-D technology can also help prevent your teeth from starting to drift the minute your braces come off. (Teeth do that.)

When the orthodontist removes your braces, she “wants a retainer in your mouth — now,” Beierle said.

Under the old method, a direct impression (another mouthful of putty) had to be taken once the braces were off.

A patient then had to wait until the retainer was made and show up for a fitting.

“Now a doctor scans your mouth two weeks before the braces come off, and we digitally remove the bands and brackets,” Beierle said.

“The braces come off and you’re handed a retainer,” he said.

Beierle, a former “brace face,” knows his hardware. As a kid, he had extreme crowding and an underbite: “I looked like a little bulldog,” he laughed.

Speaking of dogs, Beierle’s father, who founded the lab in 1973, once created a retainer for an expensive show dog.

“His lower teeth jutted out,” Beierle said. Correcting the little dog’s bite marked his return to the ring.

Beierle’s father, who still works at the lab, “loves the new technology,” Beierle said.

“But he’s glad it was me — and not him — that had to learn it.”

Janice Podsada; jpodsada@heraldnet.com; 425-339-3097; Twitter: JanicePods

Talk to us

> Give us your news tips.

> Send us a letter to the editor.

> More Herald contact information.